When it comes to manufacturing, two terms that often come up are OEM and ODM. Both are related to contracting out the production of a product but have different meanings and implications. Let’s take a closer look at what OEM and ODM actually mean.

OEM, or Original Equipment Manufacturer, refers to a company that designs and produces a product based on another company’s specifications. The OEM is responsible for the entire manufacturing process, from design and development to assembly and packaging. The end product is then sold under the original company’s brand name. In essence, the OEM acts as a custom manufacturer for the original company, creating a product according to their specific requirements.

On the other hand, ODM, or Original Design Manufacturer, refers to a company that designs and manufactures a product based on their own specifications. Unlike OEM, where the manufacturer produces a product according to another company’s design, ODM allows for more customization and flexibility. The ODM takes care of designing, manufacturing, and assembling the product, which is then sold under their own brand or label. This makes them both the designer and manufacturer of the product.

In summary, OEM and ODM are two different approaches to contract manufacturing. OEM refers to a company that produces a product based on another company’s design, while ODM refers to a company that designs and manufactures a product based on their own specifications. Understanding the difference between these two terms is crucial when looking for a manufacturer or supplier for your product.

Contents

- 1 What is OEM?

- 2 What is ODM?

- 3 Key Differences between OEM and ODM

- 4 Choosing the Right Option for Your Business

- 5 FAQ about topic “OEM and ODM Meaning: Understanding the Difference”

- 6 What is OEM?

- 7 What is ODM?

- 8 What is the difference between OEM and ODM?

- 9 Can a company be both an OEM and an ODM?

- 10 Which is better, OEM or ODM?

What is OEM?

OEM stands for Original Equipment Manufacturer. In the context of product development, OEM refers to a company or a producer that designs and manufactures products based on the specifications provided by another company. The OEM company is responsible for the entire production process, from design to assembly, and delivers the final product to the client.

The OEM is typically contracted by the client, who is usually a brand or a company that wants to sell products under their own brand name. The client provides the OEM with the specific requirements, such as product features, design, and customization options. The OEM then uses its expertise to develop and manufacture the product according to these specifications.

One of the key benefits of OEM is that it allows companies to outsource the design and manufacturing process to a specialized manufacturer. This enables the client company to focus on other core aspects of their business, such as marketing and distribution. Additionally, OEM provides cost savings as the client does not have to invest in their own production facilities or hire a dedicated manufacturing team.

OEM is commonly used in industries such as electronics, automotive, and consumer goods, where products are often complex and require specialized manufacturing techniques. By partnering with an OEM, companies can leverage the OEM’s expertise and resources to bring their product ideas to life.

Definition and Explanation

When it comes to the manufacturing industry, there are two terms that are often used interchangeably but have distinct meanings: OEM and ODM. Both refer to different approaches in the designing and production of custom products.

OEM, or Original Equipment Manufacturer, is a term used to describe a company that designs and manufactures a product that is eventually sold under another company’s brand. In other words, the OEM is responsible for the design and assembly of the product, but it is the other company that sells and markets the product under their own brand.

On the other hand, ODM, or Original Design Manufacturer, refers to a company that not only manufactures the product but also designs and develops it. ODMs offer a full package that includes both the manufacturing and design aspects of the product. They take the client’s specifications and ideas and turn them into a finished product.

With OEM, the manufacturer’s role is limited to producing the product based on the specifications provided by the buyer. However, with ODM, the manufacturer takes more responsibility for the development process and offers a more customized solution.

Both OEM and ODM involve some form of contract manufacturing and outsourcing. OEMs and ODMs often work with multiple buyers and customers, providing them with the necessary equipment and resources for manufacturing and customization.

In summary, OEM refers to a manufacturer that produces a product based on another company’s design and sells it under their brand, while ODM refers to a manufacturer that not only produces but also designs the product. Understanding the difference between these two terms is crucial for anyone involved in the manufacturing industry.

Examples of OEM Products

To better understand the meaning of OEM (Original Equipment Manufacturer) products, it is helpful to look at some examples. In the realm of electronics, an OEM manufacturer may produce custom assemblies for various products. For instance, an OEM manufacturer might design and manufacture the internal components of a smartphone, such as the motherboard, processor, or memory. These customized parts are then integrated into the final product by the smartphone producer.

Another example can be found in the automotive industry. An OEM manufacturer might be contracted to produce different parts for a car, such as the engine, transmission, or suspension system. These customized components are designed and manufactured according to the specifications provided by the car manufacturer and are then assembled on the production line.

OEM products are not limited to electronics or automotive sectors. In the fashion industry, an OEM manufacturer may produce custom clothing or accessories for a well-known brand. The clothing brand may provide the design and concept, and the OEM producer will handle the manufacturing process to ensure the final products are made to their specifications.

In the field of personal computers, an OEM supplier may produce custom computer systems for a technology company. These systems are typically designed according to the requirements of the company and may include specialized hardware or software configurations. The OEM supplier handles the production and assembly of these custom computer systems.

These examples illustrate how OEM products involve customization and manufacturing according to the specifications provided by the brand or company. OEM manufacturers play a crucial role in the design and development of products, bringing the original manufacturer’s concept to life through their expertise and manufacturing capabilities.

What is ODM?

ODM, or Original Design Manufacturer, is a type of contract manufacturing where a supplier takes on the responsibility of designing and developing a product according to the specifications provided by the buyer. In the ODM model, the supplier acts as both the designer and producer of the product. They are responsible for the custom design, development, and manufacturing of the product, based on the buyer’s requirements.

The ODM meaning revolves around the supplier’s ability to provide a complete solution, from design to production. The buyer typically provides the ideas and requirements for the product, and the supplier uses its expertise in design and manufacturing to turn those ideas into a finished product. ODM is commonly used in industries such as electronics, automotive, and consumer goods.

Unlike OEM (Original Equipment Manufacturer), where the buyer provides the design and the manufacturer is responsible for the assembly and manufacturing, ODM allows the buyer to outsource the entire design and development process to the supplier. This means that the buyer does not need to have in-house design capabilities or manufacturing facilities. Instead, they can rely on the ODM supplier’s expertise.

A key advantage of ODM is its ability to offer custom-made products that meet the unique requirements of the buyer. The supplier can tailor the design, features, and specifications of the product according to the buyer’s needs, resulting in a unique product that stands out in the market. Additionally, ODM allows the buyer to focus on marketing and selling the product, rather than investing time and resources in design and development.

In summary, ODM is a type of contract manufacturing where a supplier takes on the responsibility of designing and developing a custom product based on the buyer’s requirements. The supplier acts as both the designer and manufacturer, providing a complete solution from design to production. ODM allows the buyer to outsource the design and development process and receive a unique product that meets their specific needs.

Definition and Explanation

In the world of manufacturing, there are two terms that are often used interchangeably: OEM and ODM. While they may seem similar, they actually have distinct meanings and roles in the production process.

OEM stands for Original Equipment Manufacturer. It refers to a company that designs and manufactures a product based on the specifications provided by another company, known as the OEM contract producer. The OEM contract producer is responsible for the manufacturing of the product, while the OEM is responsible for its design and development.

ODM, on the other hand, stands for Original Design Manufacturer. Unlike OEM, ODM companies are not involved in designing the product. Instead, they are tasked with manufacturing the product based on the specifications provided by the buyer or customer. ODM suppliers specialize in the customization and manufacturing of products according to the buyer’s requirements.

Both OEM and ODM involve outsourcing the manufacturing process to a separate supplier or manufacturer. However, the key difference lies in the level of involvement in the product development and design process. OEM companies take on the responsibility of designing and developing the product, while ODM companies focus solely on manufacturing.

Overall, OEM and ODM play vital roles in the manufacturing industry. OEM manufacturers provide the necessary design and development expertise, while ODM suppliers offer customized manufacturing services. Understanding the difference between these two terms can help businesses make informed decisions when it comes to product development, design, and customization.

Examples of ODM Products

ODM, which stands for Original Design Manufacturer, refers to the manufacturing process in which a producer designs and manufactures a product based on the specifications provided by another company. ODM products are often created for OEMs (Original Equipment Manufacturers) that outsource design and production to a specialized manufacturer.

One example of an ODM product is a custom-made smartphone. In this case, the OEM provides the ODM manufacturer with specific requirements and design preferences for the phone. The ODM manufacturer then takes these specifications and develops the smartphone, including the design, customization, and manufacturing.

Another example of an ODM product is a contract assembly product. This could be a specialized device or equipment that requires a specific design and assembly process. The OEM company provides the specifications and requirements to the ODM manufacturer, who then designs and assembles the product according to the OEM’s needs.

The meaning of ODM is closely related to the concept of customization. ODM products are made to order and can be customized to meet the specific needs and branding requirements of the OEM. This level of customization sets ODM products apart from OEM products, which are generally less flexible in terms of design and functionality.

In summary, examples of ODM products include custom-made smartphones, contract assembly products, and other specialized equipment that is designed and manufactured by an ODM manufacturer based on the specifications provided by an OEM. ODM products offer a higher level of customization and flexibility compared to OEM products, making them an attractive option for companies looking to outsource their design and manufacturing processes.

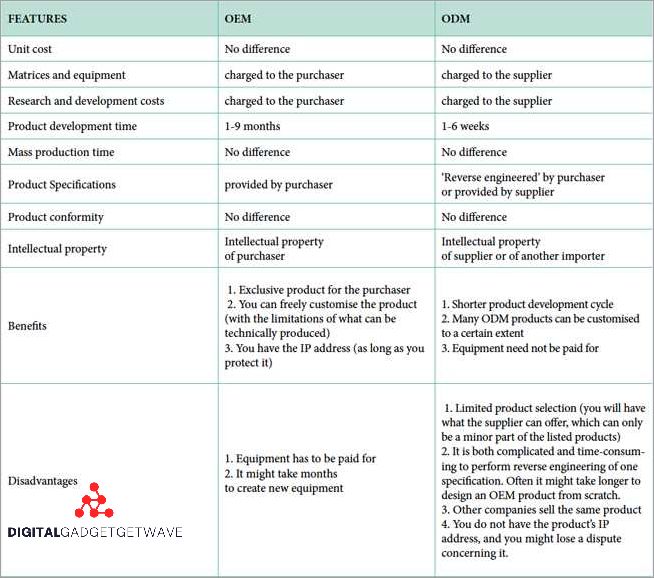

Key Differences between OEM and ODM

The terms OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are often used in the manufacturing industry to describe different types of business relationships. While both involve outsourcing the production of goods, there are key differences between the two.

OEM refers to a contract between a producer and a manufacturer, where the manufacturer produces goods based on the designs and specifications provided by the producer. In this arrangement, the manufacturer is responsible for the manufacturing and assembly of the product, while the producer retains ownership of the design and brand. The customization of the product is limited to the producer’s specifications.

On the other hand, ODM refers to a contract between a producer and a supplier, where the supplier not only manufactures the product but also designs it. In this arrangement, the supplier takes on the responsibility of both manufacturing and designing the product, based on the producer’s requirements. The producer has more flexibility in customizing the product to meet their specific needs.

Another key difference between OEM and ODM is the level of involvement the producer has in the product development process. In OEM, the producer is primarily involved in the initial design and development of the product, and then outsources the manufacturing to a third-party manufacturer. In ODM, the producer relies on the supplier for both the design and manufacturing of the product, with minimal involvement in the development process.

Overall, while both OEM and ODM involve outsourcing the production of goods, the main difference lies in the level of customization and the producer’s involvement in the design and development process. OEM is more focused on manufacturing and assembly, with limited customization, while ODM allows for greater customization and involvement in the product design.

Overview of OEM and ODM

OEM stands for Original Equipment Manufacturer. In the context of manufacturing, OEM refers to the process of designing and producing a product according to the specifications and requirements given by the customer. In this arrangement, the manufacturer acts as a supplier, producing the product based on the customer’s design and specifications.

ODM stands for Original Design Manufacturer. ODM refers to a manufacturer who not only produces a product but also designs and develops it. Unlike OEM, where the manufacturer follows the customer’s design, an ODM takes charge of the entire product development process.

In OEM, the manufacturer’s role is primarily in the production and assembly of the product. They may use their manufacturing facilities and expertise to bring the customer’s design to life. OEM also involves customization, where the manufacturer modifies the existing product according to the customer’s requirements, such as adding logos or making small design changes.

On the other hand, in ODM, the manufacturer is responsible for the design, development, and production of the product. They may use their own expertise and resources to create a completely original product, which can later be sold under the customer’s brand. ODM also allows for customization, where the manufacturer can tailor the product according to the customer’s specific needs.

Contract manufacturing is a common practice in both OEM and ODM. It refers to the process of outsourcing the manufacturing of a product to a third-party producer. The contract manufacturer is responsible for the production, assembly, and quality control, while the customer retains control over the design and intellectual property rights.

In summary, OEM and ODM have different meanings in the manufacturing industry. OEM involves the production and assembly of a product based on the customer’s design, while ODM includes the design, development, and production of an original product. Both OEM and ODM offer customization options and often involve contract manufacturing arrangements between the customer and the manufacturer.

Different Approaches to Design and Production

In the world of manufacturing, there are different approaches to designing and producing products. One approach is the OEM, or Original Equipment Manufacturer, meaning that the producer of the product designs and manufactures it according to the specifications of the customer. In this case, the customer often provides the design or concept, and the OEM takes care of the manufacturing process.

On the other hand, there is also the ODM, or Original Design Manufacturer, approach. With ODM, the manufacturer takes care of both the design and production of the product. ODMs typically have their own in-house design and development teams, and they create products based on their own ideas and market research. These products are then presented to customers for customization and branding.

Another approach is contract manufacturing, which involves a producer manufacturing products for a brand or company based on their specifications. In this case, the manufacturer is responsible for the entire production process, from sourcing materials to assembly and packaging. The contract manufacturer may also provide input on design improvements or cost optimization.

Custom manufacturing is another option, where a manufacturer creates unique products according to the specific requirements of the customer. This approach involves close collaboration between the manufacturer and the customer to ensure that the end product meets all the desired specifications. Custom manufacturing is often used for niche or specialized products that require a high degree of customization.

Outsourcing is a common practice in the manufacturing industry, where a brand or company hires a supplier or manufacturer to produce their products on their behalf. This can include both OEM and ODM approaches, depending on the level of involvement the brand wants in the design and production process. Outsourcing allows companies to focus on other aspects of their business while relying on the expertise and capabilities of the manufacturer or supplier.

In conclusion, there are various approaches to designing and manufacturing products, including OEM, ODM, contract manufacturing, custom manufacturing, and outsourcing. Each approach has its own advantages and considerations, and the choice depends on the specific needs and requirements of the brand or company.

Pros and Cons of OEM and ODM

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are two different approaches to manufacturing. Each approach has its pros and cons, and it is essential to understand them before making a decision.

Pros of OEM:

- Contracting with an OEM allows you to focus on other aspects of your business, such as marketing and sales, as the OEM takes care of the manufacturing process.

- You can benefit from the OEM’s expertise in product development and manufacturing, which can result in high-quality products.

- OEMs often have established relationships with suppliers, which can lead to cost savings on components and materials.

- Customization is possible with OEM, allowing you to have products tailored to your specific needs and branding.

Cons of OEM:

- Outsourcing manufacturing to an OEM means giving up control over the production process. You rely on the OEM to deliver quality products on time.

- The OEM’s customization capabilities may be limited compared to an ODM, as they primarily work with the manufacturer’s existing designs.

- The cost of manufacturing with an OEM can be higher, especially for small-scale production runs, as the OEM may charge additional fees for customization.

- If the OEM is unable to meet your production needs or experiences production issues, it may cause delays or disruptions in your supply chain.

Pros of ODM:

- Working with an ODM provides access to their expertise in product design and development. They can help bring your ideas to life and create innovative products.

- ODMs often have more flexibility in customization, as they specialize in designing and manufacturing original products.

- By collaborating with an ODM, you can benefit from their knowledge of the latest manufacturing technologies and trends.

- If you are a startup or a small business, partnering with an ODM can be a cost-effective solution as they typically offer lower minimum order quantities.

Cons of ODM:

- When working with an ODM, you may have less control over the manufacturing process compared to an OEM. This can make it challenging to address any production issues or make changes quickly.

- There may be limitations in the ODM’s capabilities, as they may focus on specific industries or product categories.

- With ODM, you may face challenges in protecting your intellectual property, as the ODM will have access to your designs and product specifications.

- ODM solutions may not be suitable for businesses that require highly customized or unique products, as ODMs often work with their existing designs.

In conclusion, both OEM and ODM have their advantages and disadvantages. The choice between them depends on your specific business needs, budget, and product requirements. Understanding the meaning and differences between OEM and ODM can help you make an informed decision for your manufacturing and design needs.

Choosing the Right Option for Your Business

When it comes to manufacturing and development, businesses have several options to consider. One of the key decisions to make is whether to go with OEM or ODM. Understanding the meaning and difference between these two terms is crucial in making the right choice for your business.

OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products based on another company’s design and specifications. In this arrangement, the OEM producer typically uses the manufacturer’s brand name and logo on the products. This option is suitable for businesses that have already developed a custom design and are looking for a reliable manufacturing partner to produce their products at scale.

ODM (Original Design Manufacturer)

ODM, on the other hand, involves a manufacturer that designs and manufactures a product based on their own specifications. In this case, the ODM supplier takes care of the entire product development process, from designing to manufacturing and assembly. ODM is a better option for businesses that do not have a specific design in mind and are seeking a complete solution from a manufacturer.

Choosing between OEM and ODM depends on the specific needs and goals of your business. If you already have a custom design and want to outsource the manufacturing process, OEM is the way to go. On the other hand, if you are looking for a manufacturer to handle the entire product development and customization, ODM is the right choice. It’s important to carefully evaluate your requirements and communicate them with potential manufacturing partners to ensure a successful collaboration.

Factors to Consider

When deciding whether to work with an OEM or ODM supplier, there are several factors that need to be considered:

- Design: Do you have a specific design in mind for your product? If so, an OEM supplier may be the better choice, as they can customize an existing product design to meet your requirements. On the other hand, if you are looking for a completely unique product design, an ODM supplier may be more suitable, as they specialize in product development and customization.

- Contract: Consider the contract terms offered by both OEM and ODM suppliers. OEM suppliers typically offer standardized contracts, while ODM suppliers may be more flexible in terms of customization and development. Evaluate which contract terms align with your business needs.

- Manufacturer’s Expertise: Assess the expertise and capabilities of the manufacturer. OEM suppliers are typically experts in manufacturing and assembly, while ODM suppliers excel in product development and customization. Determine which expertise is more important for your project.

- Original Equipment: If you require original equipment, an OEM supplier is more suitable, as they manufacture products under a brand’s name. ODM suppliers, on the other hand, produce products under their own brand or provide white-label products for other brands.

- Customization: Evaluate the level of customization required for your product. OEM suppliers may offer limited customization options, while ODM suppliers specialize in customization and can provide a wide range of options.

- Manufacturing Facilities: Consider the manufacturing facilities of the supplier. OEM suppliers often have established manufacturing facilities, while ODM suppliers may rely on outsourcing for manufacturing. Evaluate which approach is more suitable for your project.

By carefully considering these factors, you can make an informed decision on whether to work with an OEM or ODM supplier based on your specific needs and requirements.

Finding the Balance

When it comes to OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer), finding the right balance is crucial. For OEM, the manufacturer designs and produces the product according to the specifications provided by the client. This means that the client has more control over the final product, including customizations and branding. However, outsourcing the manufacturing process to an OEM supplier may result in higher costs and less control over the production timeline.

On the other hand, ODM offers a different approach. The ODM supplier takes care of the entire product development process, from design to assembly. This can be beneficial for clients who want to focus on their core business and leave the product design and manufacturing to the experts. ODM also allows for greater flexibility in terms of customization options, as the supplier already has the necessary infrastructure and expertise to create custom products.

However, relying on ODM can also have its drawbacks. Clients may have less control over the design and quality of the product, as they are not directly involved in the development process. Additionally, the customization options may be limited to what the ODM supplier already offers in their portfolio.

To find the right balance between OEM and ODM, it is important for clients to clearly define their requirements and evaluate their priorities. If customization and control over the product are essential, an OEM approach may be more suitable. On the other hand, if efficiency and cost-effectiveness are the main concerns, ODM can be a viable option.

Ultimately, the choice between OEM and ODM depends on the specific needs of the client and the nature of the product. It is important to thoroughly research and evaluate potential suppliers to ensure that they can meet the requirements and deliver a high-quality product. Finding the right balance between OEM and ODM can lead to successful partnerships and ultimately, a successful product in the market.

FAQ about topic “OEM and ODM Meaning: Understanding the Difference”

What is OEM?

OEM stands for Original Equipment Manufacturer. It refers to a company that manufactures products or components that are marketed by another company under its own brand name. OEMs typically make products based on the specifications provided by the company that sells the product.

What is ODM?

ODM stands for Original Design Manufacturer. It refers to a company that designs and manufactures products based on the specifications provided by another company, which then sells the product under its own brand name. ODMs are responsible for the entire product development process, from concept to production.

What is the difference between OEM and ODM?

The main difference between OEM and ODM is the level of involvement in the product development process. OEMs focus on manufacturing products based on provided specifications, while ODMs are involved in both the design and manufacturing process. OEMs mainly produce products for other companies, while ODMs produce products that are sold under another company’s brand name.

Can a company be both an OEM and an ODM?

Yes, a company can be both an OEM and an ODM. Some companies have the capability to manufacture products based on specifications provided by other companies (OEM) and also have the ability to design and manufacture products based on their own specifications (ODM). This allows them to serve a wider range of customers and have greater flexibility in their business operations.

Which is better, OEM or ODM?

The choice between OEM and ODM depends on the specific needs and goals of a company. OEM is suitable for companies that want to focus on branding and marketing, as they can leverage the expertise and resources of the OEM for manufacturing. ODM is suitable for companies that want more control over the design and development process, as they can work closely with the ODM to create products tailored to their specifications. Ultimately, the better option is the one that aligns with a company’s strategies and objectives.