Proximity sensors are widely used in various industries and applications for detecting the presence or absence of objects within a certain range. These sensors work by generating a field or beam and detecting changes in the field caused by the presence of an object. There are several different types of proximity sensors available, each using a different technology to detect objects.

One of the most common types of proximity sensors is the through-beam sensor. This sensor consists of a separate transmitter and receiver that are positioned opposite each other. When an object passes between the transmitter and receiver, it interrupts the beam, triggering the sensor. Through-beam sensors are highly accurate and can detect objects over long distances, but they require precise alignment.

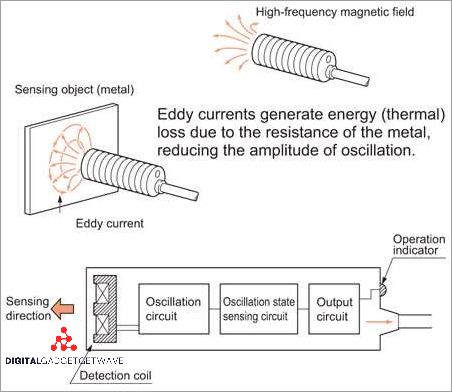

Inductive sensors are another popular type of proximity sensor. These sensors use an electromagnetic field to detect the presence of metallic objects. When a metallic object comes into proximity of the sensor, it induces eddy currents in the object, causing a change in the electromagnetic field. This change is then detected by the sensor, indicating the presence of the object.

Hall effect sensors are used to detect the presence of magnetic fields. These sensors work on the principle of the Hall effect, which states that when a current-carrying conductor is placed in a magnetic field, a voltage is produced perpendicular to both the current and the magnetic field. Hall effect sensors are commonly used in applications such as speed sensing and position sensing.

Diffuse sensors, also known as contactless or optical sensors, use a light source and a receiver to detect the presence of objects. These sensors emit a beam of light and detect the light reflected back from an object. If the object is present, the received light intensity will change, indicating the presence of the object. Diffuse sensors are commonly used in various industries, including packaging, automation, and manufacturing.

Microwave sensors use radio waves to detect the presence of objects. These sensors emit continuous microwave signals and detect changes in the reflected signals caused by objects within their range. Microwave sensors are commonly used in automatic door openers, traffic control systems, and security systems.

Reflective sensors, also known as retro-reflective sensors, consist of a transmitter and receiver that are positioned next to each other. The transmitter emits a beam of light, which is reflected back by a reflector placed opposite to the sensor. When an object comes between the sensor and the reflector, the reflected light is interrupted, indicating the presence of the object.

Capacitive sensors detect the presence or absence of objects by measuring changes in capacitance. These sensors generate an electrical field and when an object with a different dielectric constant enters the field, the capacitance changes, triggering the sensor. Capacitive sensors are commonly used in level sensing, object detection, and proximity sensing applications.

Ultrasonic sensors use sound waves at frequencies above the human hearing range to detect objects. These sensors emit ultrasonic waves and measure the time it takes for the waves to bounce back after hitting an object. By calculating the time delay, the sensor can determine the distance to the object. Ultrasonic sensors are commonly used in parking assist systems, obstacle detection, and industrial automation.

Photoelectric sensors, also known as infrared (IR) sensors, use light emission and detection to detect the presence of objects. These sensors consist of a transmitter and receiver that are positioned opposite each other. The transmitter emits an infrared light beam, which is then detected by the receiver. When an object comes between the transmitter and receiver and interrupts the beam, the receiver no longer detects the infrared light, indicating the presence of the object.

In conclusion, there are various types of proximity sensors available, each using different technologies to detect the presence or absence of objects. Through-beam, inductive, hall, diffuse, microwave, reflective, capacitive, ultrasonic, and photoelectric sensors all have their own advantages and are used in a wide range of applications. Understanding the different types of proximity sensors can help in choosing the right sensor for a specific application.

Contents

- 1 What are Proximity Sensors?

- 2 Importance of Proximity Sensors

- 3 Applications of Proximity Sensors

- 4 Inductive Proximity Sensors

- 5 Capacitive Proximity Sensors

- 6 Ultrasonic Proximity Sensors

- 7 FAQ about topic “Understanding Different Types of Proximity Sensors”

- 8 What are proximity sensors?

- 9 How do infrared proximity sensors work?

- 10 What are the applications of ultrasonic proximity sensors?

- 11 Can proximity sensors detect non-metallic objects?

- 12 What is the difference between normally open and normally closed proximity sensors?

What are Proximity Sensors?

Proximity sensors are a type of sensors that detect the presence or absence of an object by using various technologies. These sensors are commonly used in industrial automation and robotics to perform tasks such as object detection, position sensing, and control.

There are several types of proximity sensors available, each utilizing different technologies to detect objects. Some common types include through-beam, infrared, optical, reflective, contactless, capacitive, NFC (Near Field Communication), microwave, IR (infrared), magnetic, proximity, radiofrequency, inductive, diffuse, retro-reflective, and photoelectric sensors.

Through-beam sensors consist of a transmitter and a receiver placed opposite to each other. They work by detecting an object when it interrupts the beam between the transmitter and receiver.

Infrared sensors use infrared light to detect the presence of an object. They emit infrared light and measure the reflection or absorption of the light to determine if an object is present or not.

Optical sensors use light to detect the presence of an object. They emit a beam of light and measure the amount of light reflected back to determine the presence or absence of an object.

Reflective sensors emit a beam of light and measure the reflection of the light to determine if an object is present or not. These sensors are commonly used in applications where the object being detected is reflective.

Contactless sensors, such as capacitive sensors, use the principle of capacitance to detect objects. These sensors can detect the presence of both conductive and non-conductive objects without physical contact.

NFC (Near Field Communication) sensors use radiofrequency technology to enable communication between two devices placed in close proximity. These sensors are commonly used in applications such as mobile payments and data transfer.

Microwave sensors emit microwave radiation and measure the reflection or absorption of the radiation to detect the presence of an object.

IR (infrared) sensors use infrared radiation to detect the presence of an object. They emit infrared radiation and measure the reflection or absorption of the radiation to determine if an object is present or not.

Magnetic sensors use magnetic fields to detect the presence of an object. They can detect the presence of ferromagnetic materials and measure the strength of the magnetic field to determine the distance to the object.

Proximity sensors, also known as proximity switches, are used to detect the presence or absence of an object without physical contact. They can detect the presence of objects through various means, including light, sound, and capacitance.

Radiofrequency sensors use radio waves to detect the presence of an object. They emit radio waves and measure the reflection or absorption of the waves to determine if an object is present or not.

Inductive sensors use the principle of electromagnetic induction to detect the presence of an object. They emit an electromagnetic field and measure the change in the field to determine if an object is present or not.

Diffuse sensors emit a beam of light and measure the reflection of the light to determine if an object is present or not. These sensors are commonly used in applications where the object being detected is non-reflective.

Retro-reflective sensors use a reflector to bounce the emitted light back to the sensor. They measure the reflection of the light to determine if an object is present or not.

Photoelectric sensors use a combination of light and photocells to detect the presence of an object. They emit light and measure the reflection or absorption of the light to determine if an object is present or not.

Importance of Proximity Sensors

Proximity sensors are an important component in many industries and applications. They play a crucial role in detecting the presence, absence, or proximity of objects without any physical contact. Proximity sensors come in various types, such as reflective, optical, hall, retro-reflective, diffuse, sensors, microwave, IR, types, magnetic, through-beam, contactless, photoelectric, NFC, proximity, ultrasonic, capacitive, infrared, and radiofrequency.

One of the main reasons proximity sensors are important is their ability to provide contactless detection. This means they can detect the presence or absence of an object without physically touching it. This contactless feature is particularly beneficial in industries where maintaining a sterile or clean environment is crucial, such as in the medical or food processing industries.

Proximity sensors also play a vital role in automation and robotics. They can be used to detect the position or movement of objects, allowing robots to perform tasks accurately and efficiently. For example, in manufacturing plants, proximity sensors can be used to detect the presence of raw materials, monitor the speed of conveyor belts, or ensure precise positioning of components.

Another important aspect of proximity sensors is their ability to detect objects in harsh or challenging environments. For example, capacitive proximity sensors can detect non-metal objects, such as liquids or plastics, in environments where other sensors may fail. Ultrasonic proximity sensors can detect objects in dusty or foggy environments, making them suitable for outdoor applications.

In summary, proximity sensors are essential in various industries and applications. They provide contactless detection, play a crucial role in automation and robotics, and can function in challenging environments. With their wide range of types, proximity sensors offer solutions for different detection needs.

Applications of Proximity Sensors

Proximity sensors are used in a wide range of applications across various industries. They can detect the presence, absence, or proximity of an object without physical contact. Let’s explore some common applications of proximity sensors:

- Automatic door systems: Proximity sensors, such as infrared (IR) and microwave sensors, are commonly used in automatic door systems. These sensors detect the presence of a person or object and trigger the opening and closing of doors accordingly.

- Industrial automation: Proximity sensors, including inductive and capacitive sensors, are extensively used in industrial automation. They can detect the presence or absence of objects on production lines, triggering automated processes or controlling robotic arms.

- Robotics: Proximity sensors play a crucial role in robotics applications. They enable robots to navigate their environment by detecting obstacles and adjusting their movements accordingly. Sensors like ultrasonic, infrared, and through-beam can be used in robotic systems.

- Collision avoidance systems: Proximity sensors, such as ultrasonic and laser sensors, are commonly used in collision avoidance systems for vehicles. These sensors can detect objects in the vehicle’s vicinity and alert the driver or trigger automated braking systems.

- Position and level sensing: Proximity sensors, such as hall sensors, are used for position and level sensing in various applications. They can detect the presence or absence of a magnetic field, allowing for accurate positioning or level measurement in systems like elevators, conveyor belts, and fluid tanks.

- Object detection: Proximity sensors are widely used for object detection in applications such as packaging and sorting systems. Sensors like optical, photoelectric, and reflective sensors can detect the presence, absence, or position of objects on a conveyor belt or in a production line.

- Near field communication (NFC): Proximity sensors are essential components in NFC technology, which enables contactless communication and data exchange between devices. NFC sensors detect the presence of other NFC-enabled devices and facilitate various applications like mobile payments and access control systems.

In conclusion, proximity sensors have diverse applications ranging from automatic door systems and industrial automation to robotics and collision avoidance. Different sensor types, such as magnetic, IR, radiofrequency, microwave, hall, reflective, inductive, capacitive, photoelectric, optical, ultrasonic, and NFC sensors, cater to specific application requirements.

Inductive Proximity Sensors

Inductive proximity sensors are a type of contactless sensor that detect the presence or absence of an object by generating an electromagnetic field. These sensors are commonly used in industrial applications where non-contact detection is required. Inductive proximity sensors work by emitting an electromagnetic field from a coil, and when a metal object comes into the proximity of the sensor, it disturbs the electromagnetic field, which triggers a change in the sensor’s output.

The main advantage of inductive proximity sensors is that they can detect metallic objects without making physical contact with them. This makes them ideal for applications where contact with the object being detected is undesirable, such as in dirty or hazardous environments. Inductive proximity sensors are also highly reliable and have a long operating lifespan, making them suitable for use in demanding industrial environments.

There are several types of inductive proximity sensors available, including through-beam sensors, retro-reflective sensors, and diffuse sensors. Through-beam sensors consist of a separate emitter and receiver, with the emitter sending out an infrared or visible light beam and the receiver detecting any changes in the beam caused by the presence of an object.

Retro-reflective sensors use a reflector to bounce the emitted beam back to the receiver, and any interruptions in the reflected beam indicate the presence of an object. Diffuse sensors, on the other hand, emit a beam of infrared light and measure the amount of light reflected back to the receiver. The presence of an object causes a decrease in the amount of reflected light, indicating its presence.

Inductive proximity sensors are widely used in industrial automation, robotics, and manufacturing processes, where their contactless and reliable detection capabilities are essential. They can be found in a wide range of applications, including material handling, assembly lines, packaging, and machine safeguarding. With their ability to detect metallic objects without physical contact, inductive proximity sensors play a vital role in ensuring the smooth and safe operation of many industrial processes.

Working Principle of Inductive Proximity Sensors

Inductive proximity sensors are a type of contactless proximity sensors that are widely used in various industrial applications. The working principle of inductive proximity sensors is based on the phenomenon of electromagnetic induction. These sensors are capable of detecting metallic objects without any physical contact.

The key component of an inductive proximity sensor is an oscillator that generates a high-frequency electromagnetic field. When a metallic object enters the sensing range of the sensor, it interacts with the electromagnetic field, causing a change in the inductance of the sensor. This change is detected by the sensor, which then triggers an output signal.

Inductive proximity sensors are available in different types, including shielded and unshielded versions. Shielded sensors have a metal housing that provides protection against external magnetic fields, while unshielded sensors are more sensitive to external interference. The sensing range of an inductive proximity sensor depends on factors such as the size and material of the target object.

One of the advantages of inductive proximity sensors is their ability to work in harsh environments, such as those with dust, oil, or moisture. They are also resistant to vibration and shock. However, they can only detect metallic objects and are not suitable for non-metallic materials.

- Advantages of Inductive Proximity Sensors:

- Can detect metallic objects without contact

- Work in harsh environments

- Resistant to vibration and shock

In conclusion, inductive proximity sensors operate on the principle of electromagnetic induction and are used to detect metallic objects. They offer several advantages such as contactless operation, suitability for harsh environments, and resistance to vibration and shock. However, they have limitations in terms of their inability to detect non-metallic materials.

Advantages of Inductive Proximity Sensors

Inductive proximity sensors have several advantages over other types of proximity sensors such as infrared (IR), optical, contactless, ultrasonic, capacitive, radiofrequency, and through-beam sensors:

1. Non-contact operation: Inductive proximity sensors work on the principle of detecting changes in magnetic fields, allowing them to detect objects without making physical contact. This makes them suitable for applications where contact or physical interaction with the object is not desirable or possible.

2. Wide range of sensing distances: Inductive proximity sensors can be designed to have a wide range of sensing distances, ranging from a few millimeters to several centimeters. This versatility allows them to be used in a variety of applications.

3. High operating speeds: Inductive proximity sensors are capable of detecting objects at high speeds, making them ideal for applications that require fast response times. They can detect objects moving at high speeds without compromising accuracy or reliability.

4. Immunity to environmental conditions: Inductive proximity sensors are not affected by environmental conditions such as dust, dirt, or moisture. This makes them suitable for use in harsh environments where other types of sensors may fail or require frequent maintenance.

5. Reliability: Inductive proximity sensors are known for their reliability and durability. They have a long operational life and require minimal maintenance, reducing downtime and overall costs.

6. Compact size: Inductive proximity sensors are available in compact sizes, allowing them to be easily integrated into various applications with limited space. They can be mounted in tight spaces and are compatible with different mounting options.

In summary, inductive proximity sensors offer non-contact operation, a wide range of sensing distances, high operating speeds, immunity to environmental conditions, reliability, and compact size. These advantages make them a popular choice for many industrial automation and control applications.

Limitations of Inductive Proximity Sensors

Inductive proximity sensors are widely used for detecting the presence or absence of metallic objects in industrial applications. However, these sensors do have their limitations.

- Limited Range: Inductive proximity sensors have a limited range of detection. The range depends on the size and material of the object being detected. Larger metallic objects can be detected from a greater distance compared to smaller ones.

- No Detection of Non-Metallic Objects: Inductive proximity sensors are specifically designed to detect metallic objects. They cannot detect non-metallic objects such as plastic or wood. If the application requires the detection of non-metallic objects, other types of proximity sensors like capacitive or optical sensors should be used.

- Susceptible to Interference: Inductive proximity sensors can be affected by electromagnetic interference from nearby equipment or power lines. This can result in false triggering or inaccurate detection. Proper grounding and shielding techniques should be employed to minimize the impact of interference.

- Shorter Sensing Distance for Non-Ferrous Metals: Inductive proximity sensors have a shorter sensing distance for non-ferrous metals such as aluminum or copper compared to ferrous metals like iron or steel. This limitation should be considered when selecting the appropriate sensor for a specific application.

- Cannot Detect Through Non-Metallic Materials: Inductive proximity sensors rely on the eddy currents induced in metallic objects. They cannot detect metallic objects through non-metallic materials such as plastic or rubber. If the application requires the detection of metallic objects through non-metallic materials, other types of sensors like ultrasonic or microwave sensors should be used.

Despite these limitations, inductive proximity sensors are still widely used due to their reliability, durability, and cost-effectiveness in detecting metallic objects. However, it is important to consider the specific requirements of an application and choose the appropriate type of proximity sensor accordingly.

Capacitive Proximity Sensors

Capacitive proximity sensors are contactless sensors that can detect the presence or absence of an object without physical contact. They work by generating an electromagnetic field and measuring changes in capacitance when an object enters the field. This makes them ideal for applications where physical contact with the object is not possible or desirable.

Unlike photoelectric sensors, which use light to detect objects, capacitive proximity sensors operate on a different principle. They can detect a wide range of objects, regardless of color, texture, or transparency. This makes them suitable for use in a variety of industries, such as manufacturing, automotive, and food processing.

There are various types of capacitive proximity sensors available, including through-beam, retro-reflective, and diffuse. Through-beam sensors consist of a transmitter and a receiver, which are placed opposite to each other. When an object passes between the two, it interrupts the beam, triggering the sensor. Retro-reflective sensors use a reflector to bounce the emitted beam back to the sensor. If an object blocks the beam, the sensor detects it. Diffuse sensors emit a beam and measure the reflection off the object. Based on the intensity of the reflection, the sensor determines the presence or absence of the object.

In addition to capacitive proximity sensors, there are other types of proximity sensors available, such as inductive, ultrasonic, infrared (IR), optical, reflective, hall, microwave, NFC, and radiofrequency (RF) sensors. Each of these sensors operates on a different principle and is suitable for different applications. Understanding the various types of proximity sensors can help in choosing the right sensor for a specific application.

Working Principle of Capacitive Proximity Sensors

Capacitive proximity sensors are a type of contactless proximity sensors that rely on the principle of capacitance to detect the presence or absence of an object. Unlike magnetic, infrared, or ultrasonic sensors, which rely on different physical phenomena, capacitive sensors use the change in capacitance caused by the presence of an object to determine its proximity.

The basic working principle of capacitive proximity sensors involves the generation of an electric field by the sensor. This electric field interacts with the object in its proximity, causing a change in the capacitance of the sensor. The sensor detects this change and provides an output signal that indicates the presence or absence of the object.

Capacitive proximity sensors can be used to detect a wide range of materials, including non-metallic objects such as plastics, liquids, and powders. They are commonly used in applications where other types of sensors, such as inductive or optical sensors, may not be suitable. They can be used in various industrial processes, such as level detection, object detection, and position sensing.

Unlike through-beam or retro-reflective sensors, which require both a transmitter and a receiver, capacitive proximity sensors are typically single-piece devices that incorporate both the transmitter and receiver. This makes them easy to install and maintain. They are also immune to environmental factors such as dirt, dust, and moisture, which can affect the performance of other types of sensors.

In summary, capacitive proximity sensors work by generating an electric field and detecting changes in capacitance caused by the presence of an object. They are versatile, contactless sensors that can be used to detect a wide range of materials. They are easy to install and maintain, making them a popular choice in various industrial applications.

Advantages of Capacitive Proximity Sensors

Capacitive proximity sensors offer several advantages over other types of sensors such as photoelectric, microwave, magnetic, IR, and optical sensors.

These advantages include:

- Contactless operation: Capacitive proximity sensors do not require physical contact with the target object. This makes them suitable for applications where contact may cause damage, contamination, or wear on the sensor or the target object.

- Wide range of applications: Capacitive proximity sensors can detect a variety of materials, including non-metallic objects such as plastics, liquids, and powders. This versatility makes them suitable for use in industries such as food and beverage, pharmaceutical, automotive, and assembly.

- High sensitivity: Capacitive proximity sensors can detect small changes in capacitance, allowing them to detect even subtle variations in target objects. This makes them useful for applications where precise measurements or control are required.

- Immunity to environmental conditions: Capacitive proximity sensors are not affected by factors such as temperature, humidity, or ambient light, making them reliable in a wide range of operating conditions.

- Non-contact detection: The non-contact nature of capacitance sensing means that the sensor and the target object do not need to be in direct physical contact. This makes installation and maintenance easier, as there is no need for physical adjustments or wear-related replacements.

- Compact size: Capacitive proximity sensors are typically small and compact, allowing for easy integration into various systems and applications.

In summary, capacitive proximity sensors offer contactless operation, wide adaptability to different materials, high sensitivity, immunity to environmental conditions, non-contact detection, and compact size. These advantages make them a popular choice for various industrial and commercial applications.

Limitations of Capacitive Proximity Sensors

Capacitive proximity sensors, while versatile and widely used, do have some limitations that should be considered when selecting the right sensor for a specific application.

Firstly, capacitive proximity sensors have a limited sensing range compared to other types of proximity sensors such as ultrasonic or infrared sensors. They typically have a range of a few millimeters to a few centimeters, depending on the specific model. This can be a limitation when the application requires longer sensing distances.

Another limitation is that capacitive proximity sensors can be affected by environmental factors such as changes in temperature and humidity. This can lead to false readings or unreliable performance in certain conditions. It is important to consider the environmental conditions of the application when choosing a capacitive proximity sensor.

Capacitive proximity sensors also have limitations in terms of the types of materials they can detect. They work by sensing changes in capacitance, so they are best suited for detecting materials with high dielectric constants, such as plastics and liquids. They may not be as effective at detecting materials with low dielectric constants, such as metals.

Additionally, capacitive proximity sensors can be affected by interference from nearby objects or surfaces. For example, reflective or metallic surfaces can cause false detections or affect the accuracy of the sensor readings. This can be mitigated by using shielding or applying proper spacing between the sensor and the interfering objects.

Finally, capacitive proximity sensors may not be suitable for applications that require high-speed detection or precise positioning. Their response time and accuracy may not be as fast or precise as other types of sensors, such as optical or photoelectric sensors.

In summary, while capacitive proximity sensors offer many advantages, it is important to consider their limitations, such as limited sensing range, susceptibility to environmental factors, limited material detection capabilities, susceptibility to interference, and limitations in high-speed detection and positioning applications.

Ultrasonic Proximity Sensors

Ultrasonic proximity sensors are a type of contactless proximity sensor that use the principle of sound waves to detect the presence of objects. They emit high-frequency ultrasonic sound waves and measure the time it takes for the waves to bounce back after hitting an object. This information is used to determine the distance to the object.

Ultrasonic proximity sensors are commonly used in various industries for applications such as detecting the presence of objects on a conveyor belt, measuring the level of liquids or powders in tanks, or detecting the position of objects in automated systems.

These sensors are highly versatile and can be used in a variety of environments due to their ability to operate in both indoor and outdoor settings. They are not affected by factors such as light, temperature, or color of the object being detected.

Ultrasonic proximity sensors offer a longer sensing range compared to other types of proximity sensors, such as photoelectric or inductive sensors. They can detect objects at distances ranging from a few centimeters to several meters.

One of the key advantages of ultrasonic proximity sensors is their ability to detect transparent or shiny objects, which may be challenging for other types of sensors. They are also resistant to dust, dirt, and other contaminants, making them suitable for use in harsh environments.

However, ultrasonic proximity sensors may have limitations in certain applications. For example, they may not be suitable for detecting very small objects or objects with irregular shapes. They may also be affected by factors such as air currents or acoustic interferences in the environment.

Overall, ultrasonic proximity sensors offer a reliable and accurate solution for detecting the presence of objects in a wide range of industrial and automation applications. Their versatility, long sensing range, and resistance to environmental factors make them a popular choice for many industries.

Working Principle of Ultrasonic Proximity Sensors

An ultrasonic proximity sensor is a type of contactless proximity sensor that uses sound waves to detect the presence of an object. It operates on the principle of emitting high-frequency sound waves and measuring the time it takes for the waves to bounce back after hitting an object. This time delay is used to calculate the distance between the sensor and the object.

The ultrasonic proximity sensor consists of a transmitter and a receiver. The transmitter emits ultrasonic waves, typically at a frequency of around 40 kHz, which travel through the air. When these waves encounter an object, they bounce back and are received by the receiver. The receiver then measures the time it takes for the waves to return, and this information is used to determine the distance between the sensor and the object.

One of the advantages of ultrasonic proximity sensors is their ability to detect a wide range of objects, including both solid and liquid materials. They can also be used in various environmental conditions, such as dusty or humid areas. However, ultrasonic sensors may not be suitable for certain applications where the presence of other objects or surfaces can cause interference with the sound waves.

In summary, ultrasonic proximity sensors work on the principle of emitting high-frequency sound waves and measuring the time it takes for them to bounce back. They are contactless and can detect a wide range of objects, making them suitable for various industrial and automation applications.

Advantages of Ultrasonic Proximity Sensors

Ultrasonic proximity sensors offer several advantages in various applications. One of the main advantages is their ability to detect objects without physical contact. Unlike contact sensors, ultrasonic sensors use sound waves to measure distance, making them ideal for applications where contact may not be possible or desirable, such as in fragile or sensitive materials.

Another advantage of ultrasonic proximity sensors is their ability to detect objects regardless of their material or color. Unlike optical sensors that rely on light, ultrasonic sensors use sound waves that can easily penetrate through different materials, such as plastic, glass, or metal. This makes them versatile and suitable for a wide range of applications.

Ultrasonic proximity sensors also have a longer range compared to other types of sensors. With a range that can extend up to several meters, ultrasonic sensors can be used in applications that require detection at a greater distance. This makes them ideal for use in large industrial settings or outdoor applications.

In addition, ultrasonic proximity sensors are not affected by environmental factors such as dust, dirt, or temperature changes. This ensures reliable and accurate detection, even in harsh conditions. Ultrasonic sensors are also resistant to interference from other sources, such as electromagnetic fields, making them more reliable in industrial environments.

Furthermore, ultrasonic proximity sensors offer a high level of precision and accuracy. They can measure distances with high repeatability, allowing for precise control and positioning in various applications. This makes them suitable for use in robotics, automation, and other precision-based industries.

In summary, ultrasonic proximity sensors offer several advantages over other types of sensors. Their ability to detect objects without physical contact, their versatility in detecting objects of various materials and colors, their long range, resistance to environmental factors, and high precision make them a preferred choice in many applications.

Limitations of Ultrasonic Proximity Sensors

Ultrasonic proximity sensors, like other types of proximity sensors, have their own set of limitations that should be considered when choosing the appropriate sensor for a specific application.

One of the limitations of ultrasonic proximity sensors is their limited range. These sensors typically have a maximum range of a few meters, which means they may not be suitable for applications that require longer detection distances.

Another limitation of ultrasonic proximity sensors is their susceptibility to environmental factors. For example, these sensors can be affected by air temperature and humidity, which can cause variations in their detection accuracy. Additionally, ultrasonic sensors may have difficulty detecting certain materials or surfaces, such as soft or porous objects.

Ultrasonic proximity sensors also have limitations when it comes to detecting small objects or objects with irregular shapes. Due to their wide beam angle, these sensors may have difficulty accurately detecting small or irregularly shaped objects.

Furthermore, ultrasonic proximity sensors are not suitable for applications that require high-speed or high-frequency detection. These sensors have a relatively slow response time compared to other types of proximity sensors, such as infrared or microwave sensors.

Lastly, ultrasonic proximity sensors can be affected by noise interference. This can be particularly problematic in industrial environments where there may be a lot of background noise or vibrations that can disrupt the sensor’s operation.

In summary, while ultrasonic proximity sensors have their advantages, such as being contactless and suitable for various applications, it’s important to be aware of their limitations in terms of range, environmental factors, detection accuracy, speed, and noise interference.

FAQ about topic “Understanding Different Types of Proximity Sensors”

What are proximity sensors?

Proximity sensors are devices that can detect the presence or absence of an object within a certain range without physical contact. They use different technologies such as infrared, ultrasonic, capacitive, and inductive to sense the proximity of an object.

How do infrared proximity sensors work?

Infrared proximity sensors work by emitting infrared light and detecting the reflection or absence of that light. They have an emitter and a receiver. When an object is present, the infrared light is reflected back to the receiver, triggering the sensor. If there is no reflection, the sensor remains inactive.

What are the applications of ultrasonic proximity sensors?

Ultrasonic proximity sensors are commonly used in industries for object detection, positioning, and level measurement. They can be used in automotive parking systems, robotics, security systems, and packaging machines, among others.

Can proximity sensors detect non-metallic objects?

Yes, proximity sensors can detect non-metallic objects depending on the technology used. Capacitive proximity sensors can detect most materials, including non-metallic ones like plastics and glass. However, some sensors like inductive proximity sensors are only sensitive to metallic objects.

What is the difference between normally open and normally closed proximity sensors?

Normally open proximity sensors are normally off and only activate when an object is detected. Normally closed proximity sensors are normally on and deactivate when an object is detected. The choice between the two depends on the specific application and the desired behavior of the sensor.