Fibre Bragg Grating (FBG) is an optical component that is widely used in various applications. It is a type of grating that is fabricated on an optical fiber by periodic variation of the refractive index, which creates a wavelength-specific reflector. The FBG works based on the principle of wavelength-selective reflection.

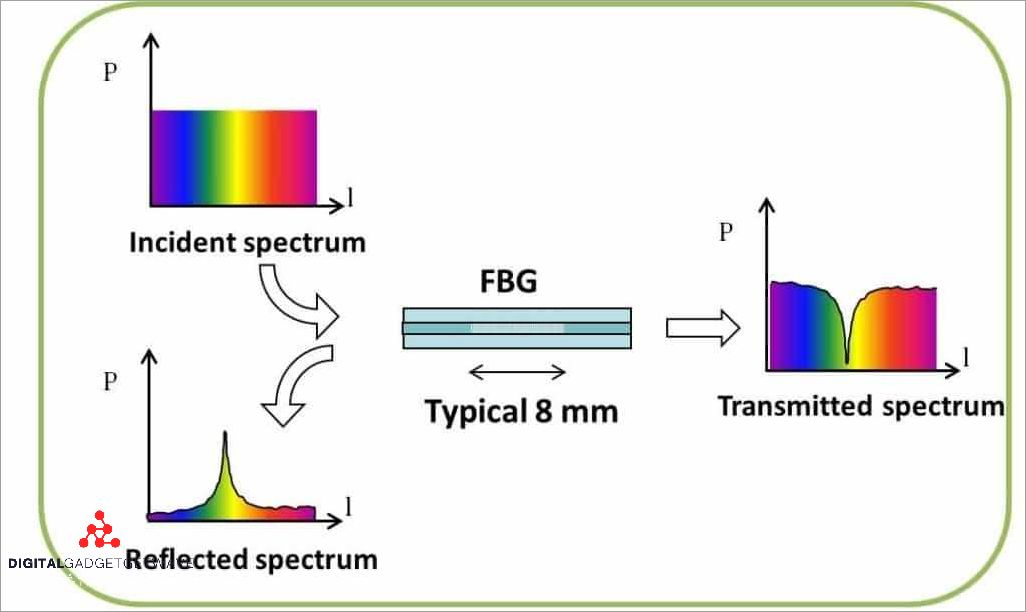

The FBG acts as a wavelength filter, reflecting a narrow range of wavelengths while transmitting the rest of the optical spectrum. The reflection band is determined by the spacing of the grating, with the reflected wavelength satisfying the Bragg condition.

FBGs are commonly used in telecommunications, fiber sensor applications, and optical measurement systems. One of their key advantages is their tunable spectral response, which can be adjusted by changing the grating period or using temperature or strain. This tunability allows for precise control of the wavelengths reflected by the grating.

FBGs are used in various sensing applications, including temperature sensing, strain sensing, and dispersion measurements. In temperature sensing, the FBG’s spectral response is sensitive to changes in temperature, allowing for accurate temperature measurements. In strain sensing, the FBG’s spectral response changes with the applied strain, enabling the measurement of strain in structures.

FBGs also exhibit excellent spectral stability over a wide range of temperatures and are immune to electromagnetic interference, making them ideal for harsh environments. They can be used as highly sensitive sensors in industries such as oil and gas, aerospace, and structural monitoring.

Contents

- 1 What is Fibre Bragg Grating?

- 2 How Does Fibre Bragg Grating Work?

- 3 Advantages and Disadvantages of Fibre Bragg Grating

- 4 FAQ about topic “Understanding Fibre Bragg Grating: A Comprehensive Guide”

- 5 What is Fibre Bragg Grating and how does it work?

- 6 What are the applications of Fibre Bragg Grating?

- 7 How accurate is Fibre Bragg Grating in measuring strain and temperature?

- 8 Are there any limitations or challenges in using Fibre Bragg Grating sensors?

- 9 Can Fibre Bragg Grating sensors be used in harsh environments?

What is Fibre Bragg Grating?

Fibre Bragg Grating (FBG) is a type of reflecting filter that consists of a periodic variation in the refractive index of an optical fibre. The periodicity of the refractive index variation is typically in the order of a few hundred nanometers, which corresponds to the wavelength of light that the grating reflects.

FBGs are used in a wide range of applications, particularly in optical sensing and measurement. They are commonly employed as sensors for measuring physical quantities such as temperature, strain, and pressure. The principle behind FBG-based sensing is the spectral shift of the reflection wavelength of the grating due to changes in the surrounding environment.

The spectral response of an FBG is determined by the fundamental principles of Bragg diffraction and interference. When light propagates through the fibre, part of it is reflected back by the grating at a specific wavelength known as the Bragg wavelength. This reflected light can be detected and analyzed using optical interrogation techniques.

One of the key advantages of FBGs is their tunable reflection wavelength. By modulating the physical parameters of the grating, such as temperature or strain, the Bragg wavelength can be shifted. This tunability allows FBG sensors to be customized for specific applications, making them highly versatile and adaptable.

FBGs also possess other unique properties that make them attractive for sensing applications. For instance, they exhibit low insertion loss, high reflectivity, and excellent stability over time. Additionally, FBGs can be easily integrated into optical fiber networks and components, making them compatible with existing infrastructure.

In summary, Fibre Bragg Grating is an optical component that uses a periodic variation in the refractive index of an optical fibre to reflect light at a specific wavelength. It is widely used in sensing and measurement applications, offering tunable reflection wavelength and excellent performance characteristics.

Definition of Fibre Bragg Grating

Fibre Bragg Grating (FBG) is an optical component that consists of a periodically varying refractive index along the length of a fibre. It acts as a reflection filter for a specific wavelength of light and can be used for a variety of applications in fibre optic sensing and measurements.

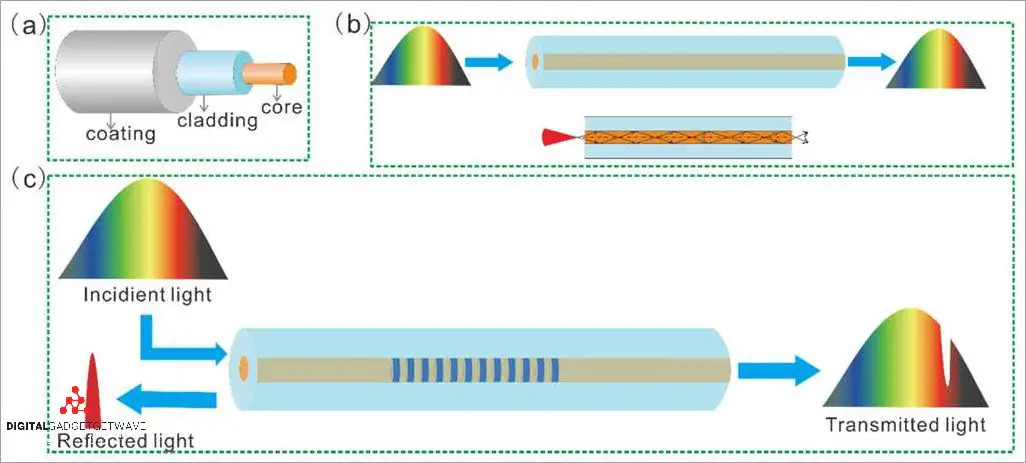

FBGs are fabricated by exposing the core of an optical fibre to a pattern of high-intensity ultraviolet light, which causes a localized change in the refractive index. The periodic variation in the refractive index acts as a diffraction grating, which reflects light of a specific wavelength back towards the source.

FBGs are commonly used as strain and temperature sensors due to their inherent stability and high sensitivity. The strain or temperature-induced changes in the FBG cause a shift in the reflected wavelength, which can be measured and used for sensing applications.

FBGs can also be used as tunable filters or wavelength-selective elements in optical communication systems. By applying an external force or changing the temperature, the FBG can be made to change its reflection wavelength, allowing for dynamic wavelength control and dispersion compensation.

The spectral characteristics of FBGs can be precisely controlled during the fabrication process, enabling the design of gratings with specific reflection properties. This makes FBGs versatile components for various applications in fibre optic sensing, telecommunications, and other industries.

In summary, Fibre Bragg Gratings are optical components that use the reflection properties of a periodic refractive index variation in an optical fibre. They are used for strain and temperature sensing, tunable filters, and other applications that require precise spectral control and measurement.

Characteristics of Fibre Bragg Grating

The key characteristic of a Fibre Bragg Grating (FBG) is its ability to reflect specific wavelengths of light. The spectral reflection properties of FBGs are determined during the manufacturing process, where the periodic variation in refractive index is created. This periodic variation, known as the grating, allows for the reflection of specific wavelengths of light, while allowing others to pass through.

FBGs are highly tunable, meaning that the reflected wavelength can be adjusted by altering the physical parameters of the grating, such as the period or the refractive index modulation depth. This tunability allows for precise control over the reflected wavelength, making FBGs versatile for various optical applications.

Another important characteristic of FBGs is their stability. FBGs exhibit high stability against external influences, such as temperature fluctuations, strain, and mechanical stress. This stability is crucial for long-term performance and reliability of FBG-based systems, making them ideal for demanding applications.

FBGs also offer excellent dispersion characteristics, which refers to the way in which the different wavelengths of light propagate through the fibre. The dispersion properties of FBGs can be controlled by manipulating the grating period. This control over dispersion allows for improved transmission and signal quality in optical communication systems.

One of the main applications of FBGs is in fibre-optic sensing. FBGs can be used as sensors to measure various physical parameters, such as temperature and strain. When the physical parameter being measured changes, it causes a shift in the reflected wavelength of the FBG. By monitoring this shift, the physical parameter can be accurately measured.

In summary, the characteristics of Fibre Bragg Gratings include their reflection properties, spectral tunability, stability against external influences, dispersion control, and their applications in optical sensing for temperature and strain measurement. These characteristics make FBGs a valuable component in a wide range of optical systems and applications.

Application of Fibre Bragg Grating

Fibre Bragg Grating (FBG) has a wide range of applications in various industries due to its unique spectral characteristics. The ability of FBGs to reflect specific wavelengths of light makes them ideal for sensing applications.

One of the main applications of FBGs is in temperature and strain measurement. By measuring the wavelength shift of the reflected light, FBGs can accurately determine the temperature or strain applied to the fibre. This makes them valuable in structural monitoring, where they can be used to detect any changes in the strain of a material or the temperature of an environment.

FBGs are also widely used in optical sensing systems. They can be used as sensors in various industries such as aerospace, civil engineering, and oil and gas. Their high sensitivity to changes in temperature and strain makes them suitable for detecting and monitoring structural integrity, pressure, and vibration.

Another application of FBGs is in optical fiber communication systems. They can be used as tunable components in the system, allowing for wavelength filtering and dispersion compensation. Their ability to reflect specific wavelengths of light makes them useful in multiplexing and demultiplexing signals.

FBGs are also used in optical fibre sensor interrogation systems. These systems are used to measure multiple FBGs simultaneously by monitoring the reflected wavelengths of light. The stability and precision of FBGs make them ideal for this application, providing accurate and reliable measurements.

In summary, Fibre Bragg Gratings (FBGs) have a wide range of applications in spectral sensing, strain and temperature measurement, optical sensing systems, optical fiber communication, and sensor interrogation. Their unique properties make them valuable in various industries where precise and reliable measurements are required.

How Does Fibre Bragg Grating Work?

Fibre Bragg Gratings (FBGs) are optical components that are used in a wide range of applications, particularly in the field of sensing and measurement. They work based on a phenomenon called the Bragg reflection.

The working principle of a Fibre Bragg Grating involves creating a periodic variation of the refractive index along the length of an optical fiber. This variation acts as a spectral filter, reflecting certain wavelengths of light while transmitting others. The distance between the reflection peaks, known as the Bragg wavelength, is determined by the period of the index variation.

FBGs are highly stable and can be designed for specific reflection wavelengths. They can be used as sensors to measure various parameters such as strain, temperature, and pressure. When subjected to external changes, the FBG will experience a shift in the Bragg wavelength, allowing for accurate measurement and monitoring.

The interrogation of FBGs can be done using different techniques, such as tunable lasers or spectrometers. By analyzing the reflected spectrum, the changes in the Bragg wavelength can be detected and interpreted to determine the environmental conditions or applied forces.

One of the key advantages of Fibre Bragg Gratings is their ability to operate in harsh environments, including high temperatures and strong electromagnetic fields. Additionally, FBGs offer excellent wavelength and spectral stability, making them suitable for long-term and reliable measurements.

Overall, Fibre Bragg Gratings play a crucial role in various optical sensing and measurement systems, providing accurate and precise data for a wide range of applications.

Working Principle of Fibre Bragg Grating

Fibre Bragg Grating (FBG) is a type of optical sensor that works based on the principle of wavelength measurement. It consists of periodic gratings inscribed within a fibre optic cable. The grating structure reflects a specific wavelength of light, called the Bragg wavelength, while allowing other wavelengths to pass through.

When light passes through the fibre Bragg grating, the reflected wavelength depends on the spacing and refractive index of the gratings. This reflection can be measured and used for various sensing applications. The grating is typically made using a photosensitive material, which alters the refractive index selectively under UV light exposure.

The key feature of fibre Bragg gratings is their tunable reflection wavelength. By changing the spacing between the gratings or modifying the refractive index, the Bragg wavelength can be shifted. This tunability allows for the measurement of various physical parameters, such as strain or temperature, by monitoring the change in reflection wavelength.

Fibre Bragg gratings are commonly used in optical sensing applications due to their high stability and sensitivity. They can be easily integrated into optical fibre systems and provide accurate measurements over a wide range of conditions. Their spectral characteristics can be interrogated using optical components and techniques, enabling precise and reliable sensing.

Thanks to their unique working principle, fibre Bragg gratings find extensive applications in many fields. They are widely used in strain and temperature sensing for structural health monitoring, where they can accurately measure changes in strain or temperature within a structure. They are also employed in dispersion compensation, where they help to mitigate the effects of optical signal distortion.

In conclusion, the working principle of fibre Bragg gratings relies on their ability to reflect specific wavelengths of light while allowing others to pass through. This reflection can be used for precise measurement of physical parameters such as strain or temperature. With their tunable reflection wavelength, high stability, and optical sensing capabilities, fibre Bragg gratings are essential components in various applications.

Formation of Fibre Bragg Grating

Fibre Bragg Gratings (FBGs) are created by a process called UV (ultraviolet) laser-induced photosensitivity in optical fibres. This process involves exposing the fibre core to a laser beam with a precise wavelength, which causes a localized change in the refractive index of the fibre.

The formation of FBGs is based on the phenomenon of spectral reflection. When light is incident on the fibre grating, a portion of the light is reflected back, depending on the grating parameters such as the period and the refractive index modulation. The reflected light is referred to as the Bragg reflection and occurs at a specific wavelength, known as the Bragg wavelength.

The formation of a FBG involves inducing strain in the fibre, which creates a periodic variation in the refractive index. This strain can be applied externally (externally-applied FBG) or induced internally within the fibre core (internally-applied FBG). The strain-induced grating results in a periodic variation of the effective index of the fibre, allowing for the reflection of a specific wavelength.

The stability and spectral characteristics of FBGs make them ideal for various sensing applications. FBGs can be used as tunable filters for wavelength interrogation and dispersion compensation in optical communication systems. They have also found applications in fiber optic sensors for temperature and strain measurement, where the Bragg wavelength shifts are utilized to measure the environmental changes affecting the fibre grating.

In summary, the formation of a Fibre Bragg Grating involves inducing strain in the fibre to create a periodic variation in the refractive index. This strain-induced grating allows for spectral reflection at a specific wavelength, which can be used for various optical sensing applications.

Key Components in Fibre Bragg Grating

In fibre Bragg grating technology, several key components play a crucial role in its operation and functionality. These components enable the spectral reflection and sensing capabilities of the grating, making it suitable for various applications.

Fiber: The fibre itself is a critical component of the fibre Bragg grating. It serves as the medium through which the optical signals travel and interact with the grating structure.

Tunable grating: A tunable grating is an essential element in fibre Bragg grating technology. It allows for the manipulation of the grating’s wavelength response, enabling filtering and sensing capabilities at different wavelengths.

Measurement and interrogation system: The measurement and interrogation system is responsible for capturing and analyzing the spectral response of the fibre Bragg grating. It provides accurate and precise measurements of parameters such as strain, temperature, and other environmental variables.

Optical sensing: Fibre Bragg gratings are widely used in optical sensing applications. They can be used as sensors for measuring strain, temperature, pressure, and other physical quantities. The grating’s spectral response changes in response to the external stimuli, allowing for accurate and reliable measurements.

Dispersion stability: The dispersion stability of the fibre Bragg grating is a crucial factor in its performance. It ensures that the grating’s spectral response remains consistent and predictable over time, even in the presence of external factors such as temperature variations or mechanical strain.

Spectral reflection: The spectral reflection capability is the fundamental property of fibre Bragg gratings. It allows the grating to reflect specific wavelengths of light while transmitting others. This property is utilized in various applications such as optical filters and wavelength division multiplexing.

Bragg gratings: Bragg gratings are the main component of fibre Bragg grating technology. They consist of periodic variations in the refractive index of the fibre core, which create the spectral reflection and sensing capabilities of the grating.

Wavelength: The wavelength at which the fibre Bragg grating reflects or transmits light can be precisely controlled through the design and fabrication of the grating structure. This property allows for the customization of the grating’s spectral response to meet specific application requirements.

Components: The various components in fibre Bragg grating technology work together to create a reliable and efficient sensing system. The combination of the fibre, tunable grating, measurement and interrogation system, and Bragg gratings enables accurate and precise measurements in a wide range of applications.

In summary, the key components in fibre Bragg grating technology include the fibre, tunable grating, measurement and interrogation system, optical sensing capabilities, dispersion stability, spectral reflection, Bragg gratings, wavelength control, and various other components. These components enable the grating’s functionality and make it a valuable tool in optical sensing and measurement applications.

Advantages and Disadvantages of Fibre Bragg Grating

Advantages:

- Dispersion Measurements: Fibre Bragg Grating (FBG) sensors are capable of measuring the dispersion properties of optical fibers, which is essential for designing and optimizing optical communication systems.

- Temperature Sensing: FBG sensors can accurately measure temperature changes by monitoring the wavelength shift in the reflected light. This makes them suitable for temperature monitoring in various industries, such as aerospace and oil and gas.

- Strain Measurement: FBG sensors can be used to measure strain by monitoring the wavelength shift caused by the strain-induced changes in the fiber’s refractive index. This enables the monitoring of structural health and integrity in applications like civil engineering and structural monitoring.

- Tunable Wavelength: The wavelength of the reflected light from FBG can be tuned by changing the grating period. This allows for the design of tunable devices and sensors.

- Interrogation Techniques: FBG sensors can be easily interrogated using simple and cost-effective detection systems, making them suitable for large-scale deployments and integration with existing optical networks.

- High Stability: FBG sensors have a high level of stability, making them reliable for long-term and continuous monitoring applications.

- Wide Range of Applications: FBG sensors find applications in various fields, including structural health monitoring, aerospace, oil and gas, medical sensing, and environmental monitoring.

Disadvantages:

- Temperature Limitations: FBG sensors may experience limitations in extreme temperature environments, which can affect their accuracy and reliability.

- Complex Setup: The setup and installation of FBG sensors can be complex, requiring precise alignment and calibration.

- Cost: FBG sensors can be relatively expensive compared to other sensing technologies, especially when used in large-scale deployments.

- Limited Measurement Range: The measurement range of FBG sensors is limited by the bandwidth of the reflection peak, which may require multiple sensors for certain applications.

- Dependency on Fiber Properties: The performance of FBG sensors is dependent on the properties of the fiber used, such as the fiber type, length, and coating.

- Environmental Sensitivity: FBG sensors can be sensitive to environmental factors, such as humidity and pressure, which may require additional protective measures or compensation techniques.

Advantages of Fibre Bragg Grating

Measurement Accuracy: Fibre Bragg Gratings (FBGs) provide highly accurate measurements due to their ability to precisely reflect a specific wavelength of light. This allows for precise measurement of various physical parameters such as temperature, strain, and pressure.

Stability: FBGs exhibit excellent long-term stability, making them highly reliable for continuous monitoring applications. They do not drift or degrade over time, ensuring consistent and accurate measurements over extended periods.

Sensor Size: FBGs are very small in size, typically a few millimeters in length, making them suitable for integration into compact sensing devices and systems. This allows for the creation of miniaturized sensors that can be easily deployed in various environments.

Optical Interrogation: FBGs can be interrogated using optical techniques, eliminating the need for electrical connections to the sensor. This makes them immune to electromagnetic interference and allows for remote and distributed sensing applications.

Tunable Wavelength: The wavelength of the FBG can be easily tuned by controlling the manufacturing process. This allows for the customization of FBGs for specific measurement requirements, making them highly versatile for a wide range of sensing applications.

Temperature Insensitivity: FBGs are inherently temperature insensitive, meaning that changes in temperature do not affect their reflection wavelength. This makes them suitable for temperature sensing applications where accurate measurements are required in a wide temperature range.

Spectral Dispersion: FBGs can be designed to have a narrow spectral dispersion, which allows for precise measurement of very small changes in the physical parameter being sensed. This high-resolution capability makes them ideal for applications requiring fine measurement sensitivity.

Reflective Design: FBGs operate based on the principle of reflection. This allows for simple and straightforward measurement techniques, as the measurement is based on the detection of the reflected wavelength. The reflective design also enables multiplexing of multiple FBGs in a single fiber, increasing the sensing capacity without the need for additional optical components.

Wide Range of Sensing Applications: FBGs can be used in a wide range of sensing applications, including structural health monitoring, oil and gas industry, aerospace industry, biomedical applications, and many more. Their versatility and reliability make them an excellent choice for various sensing needs.

Disadvantages of Fibre Bragg Grating

Fibre Bragg Grating (FBG) technology has gained popularity in various applications, thanks to its numerous advantages. However, it also has some disadvantages that need to be considered.

- Stability: FBG sensors are sensitive to changes in temperature and strain, which can affect their accuracy and reliability. The stability of FBG sensors can be improved by using temperature compensation techniques and strain relief devices.

- Optical Dispersion: FBGs exhibit a certain level of optical dispersion, which can limit their performance in some applications. This dispersion can be compensated using specialized components and design techniques.

- Tunable Wavelength Range: FBGs have a fixed reflection wavelength, which cannot be easily tuned. This limitation can restrict their use in applications where a tunable wavelength range is required.

- Complex Interrogation Systems: FBG sensors require complex interrogation systems to measure the wavelength shift accurately. These systems can be expensive and challenging to set up and maintain.

- Limited Sensing Range: FBG sensors have a limited sensing range, typically a few millimeters to a few centimeters. This range may be insufficient for certain applications that require long-range sensing.

- Environmental Sensitivity: FBG sensors can be affected by environmental factors such as humidity, pressure, and chemical exposure. These factors can degrade the performance and reduce the lifespan of the sensors.

Despite these disadvantages, Fibre Bragg Grating technology continues to be widely used in various industries for applications such as structural health monitoring, temperature sensing, and strain measurement.

FAQ about topic “Understanding Fibre Bragg Grating: A Comprehensive Guide”

What is Fibre Bragg Grating and how does it work?

Fibre Bragg Grating (FBG) is a type of optical sensor that is used to measure strain and temperature in structures. It consists of a special type of optical fiber that contains periodic variations in the refractive index. When light is sent through the FBG, a specific wavelength is reflected back, depending on the period of the index variation. By measuring this reflected wavelength, engineers can determine the strain or temperature changes in the structure.

What are the applications of Fibre Bragg Grating?

Fibre Bragg Grating has a wide range of applications in various industries. It is used in structural health monitoring of bridges, dams, and other infrastructure. It is also used in oil and gas pipelines to monitor strain and temperature. FBG sensors are used in aerospace industry to measure strain and temperature in aircraft components. Additionally, FBG sensors are used in biomedical applications for monitoring vital signs and in telecommunications for wavelength filtering.

How accurate is Fibre Bragg Grating in measuring strain and temperature?

Fibre Bragg Grating is a highly accurate sensor for measuring strain and temperature. It has a measurement accuracy of up to ±1 µε (microstrain) for strain and ±0.1 °C for temperature. The accuracy can be further improved with calibration and temperature compensation techniques. Compared to traditional electrical strain gauges, FBG sensors offer higher accuracy and reliability.

Are there any limitations or challenges in using Fibre Bragg Grating sensors?

While Fibre Bragg Grating sensors have many advantages, there are also some limitations and challenges. They require specialized knowledge and equipment for installation and maintenance. FBG sensors are sensitive to bending and twisting, so proper care needs to be taken during installation. They are also sensitive to temperature fluctuations, which can cause measurement errors if not compensated for. Lastly, FBG sensors can be costly compared to other sensing technologies.

Can Fibre Bragg Grating sensors be used in harsh environments?

Yes, Fibre Bragg Grating sensors can be used in harsh environments. They are made of durable materials and can withstand high temperatures, extreme pressures, and corrosive environments. FBG sensors can be specially designed and packaged to be resistant to water, chemicals, and vibration. This makes them suitable for applications in the oil and gas industry, aerospace, and other demanding environments.